What if you want to find alternative supply sources on very short notice, and AI helps you find them? It sounds like a miracle, but it is a reality. Unilever is already using AI in supply chain to optimize its operations. Numerous exciting examples exist depicting how AI in the supply chain helps. Also, other brands like Walmart, Maersk, and Amazon have already taken the smart move, incorporating AI into their supply chain operations.

The Global AI Supply Chain Market is set to be approximately USD 157.6 billion by 2033, reflecting a remarkable CAGR of 42.7%(2024-2033). In one recent report by Capgemini, 68% of supply chain organizations have embraced AI-driven solutions for enhanced traceability and visibility.

What do you think- what inspired supply chain businesses to adopt AI?

It is because of a multitude of benefits, such as exceptional customer experiences, better efficiency, reduced operational costs, and more.

AI-powered supply chain solutions solve key challenges and help grow businesses with sustainability. In terms of use cases, they help identify potential issues, predict failures, and provide deeper insights into operations, making AI a perfect solution for the supply chain and logistics business.

Your eagerness to embrace AI for your supply chain business brought you to the right place. This article will walk you through the most exciting information for a few minutes, helping you make the right decision about leveraging AI-powered supply chain software development services to optimize operations, enhance efficiency, and drive growth.

Let’s start!

What is AI in the Supply Chain?

Before diving into supply chain automation with AI, this is the first question you should ask yourself. The reason is simple: first, you lay down a strong foundation, then climb the ladder step-wise for successful implementation.

Artificial intelligence is a technology that mimics and simulates human intelligence to perform complex tasks. Now, here comes its subset that makes AI more powerful: Machine Learning, which makes machines learn by processing data sets.

AI systems work more advanced than traditional software and function to extract information from videos, written text, and speech, predict behavior, and make decisions based on a complex and large data set. This behavior makes it the most suitable and valuable technology for monitoring, maintaining, and optimizing supply chain workflows.

Let’s understand it through some real-life user personas:

- AI in the supply chain significantly improves automobile manufacturers’ manual review process by identifying hazardous maintenance issues, leading to better cost savings.

- A leading global industrial products manufacturer aimed at achieving zero serious incidents and fatalities by leveraging computer vision technology for safety control, generating predictive insights, and implementing targeted safety campaigns.

- AI-powered supply chain solutions can help companies handle millions of packages daily, with the expectation of increasing efficiency and reducing equipment downtime.

So specifically, AI in the supply chain serves mission-critical purposes such as Demand Forecasting, Inventory Optimization, Logistics and Transportation Route Optimization, Warehouse Management, and Supplier Management. Leveraging logistics software development services, businesses can integrate AI-driven solutions to automate processes, enhance real-time tracking, and optimize resource allocation, ultimately improving supply chain efficiency and reducing operational costs.

Now that you know how it works, this technology offers multiple benefits for all supply chain businesses.

What are these?

Let’s move to the next section!

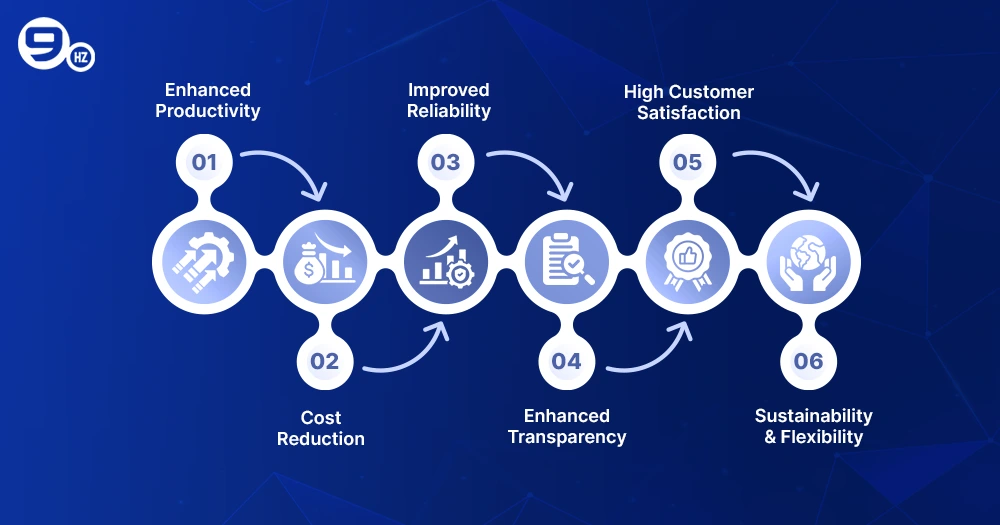

Benefits of AI in Supply Chain

Eager to know the benefits of AI in the supply chain- Right? What if AI can help you – save 70% of time with weekly planning, 15% -30 % reduce forecast errors, and 20% -40 % lower inventory costs?

Yes, consider these the real-time benefits of using AI-driven supply chain solutions. Let’s examine in detail how AI benefits supply chains.

Enhanced Productivity

The key advantage of supply chain automation with AI is automating repetitive tasks such as data entry, inventory tracking, and order processing, saving time. AI-powered algorithms help identify roadblocks and suggest optimized workflows, smoothing operations. Overall, it enhances efficiency and productivity when dealing with complex supply chain operations.

Cost Reduction

Budget and cost can sometimes be a bottleneck when maintaining supply chain operations, especially with large-scale businesses. AI offers many ways to save costs, such as Robotic Process Automation, reducing labor costs and dependencies, minimizing waste, and optimizing resource allocation.

Improved Reliability

Human errors can lead to business loss and other blunders. However, this scenario doesn’t exist when using AI-powered supply chain solutions. AI solutions are less prone to errors, can predict potential issues with operations and equipment, and accurately forecast demand, leading to seamless inventory management.

Enhanced Transparency

Another key advantage of AI in supply chains is enhanced visibility and transparency, as artificial intelligence empowers businesses to track goods in real-time, improve data management, and improve traceability to ensure compliance.

High Customer Satisfaction

AI in logistics and supply chain management helps reduce delivery times, reduce errors in order fulfillment, and offer better responsiveness. For example, AI-powered chatbots provide quick responses to customers’ queries.

Sustainability & Flexibility

Regarding sustainability, AI helps optimize routes by suggesting efficient routes and reducing fuel consumption, waste, and carbon emissions. And if you are talking about flexibility, AI—and ML-driven supply chain solutions quickly adapt to real-time market changes.

The Role of AI in Supply Chain

AI is not the future? Shocked!

Don’t take it otherwise; now, it’s a reality for multiple industries, and supply chain is one of these.

82% of supply chain organizations have already adopted AI-driven quality control and achieved an 18% reduction in production errors. This is just one fact; others exist, making the role of AI in the supply chain crucial.

AI and ML are actively transforming the supply chain industry dramatically. Their role is multifaceted, ranging from warehouse automation to predictive analysis or inventory management to ongoing equipment maintenance, ensuring the flow of goods, and meeting customers’ demands on time.

Demand Analysis

AI can analyze historical and real-time sales data and market trends. AI-powered demand analysis and forecasting, in turn, help businesses effectively plan production and optimize inventory.

Predictive Maintenance

Machinery, equipment, and vehicles are integral to supply chain operations and require monitoring and maintenance. AI is supreme here as it can predict potential bottlenecks and suggest the best proactive maintenance method with reduced costs.

Risk Mitigation

Like predictive maintenance, AI in supply chain management quickly predicts risks by analyzing market conditions, weather, historical data, and geopolitical circumstances. What could you need more to keep your business safe?

Production Planning

Manufacturing and supply chain management are proportional; both face challenges if one affects the other. AI-powered manufacturing and supply chain solutions help schedule production, analyze order priorities, and allocate resources for seamless production and delivery of goods.

Supplier Relationship

Procurers and suppliers are the pillars of the supply chain industry. Maintaining good relationships between them is a big win for business. The subset of AI, NLP, aka Natural Language processing, plays a crucial role in gaining insights and personalizing supplier communication, analyzing current relationships, identifying issues, and improving relationships.

Warehouse Management

Automation is one of AI’s superpowers, enabling supply chain businesses to optimize operations through warehouse management software development and inventory management software development. AI-powered warehouse management software streamlines processes like picking, packing, and order fulfillment, reducing manual efforts and improving accuracy. Meanwhile, inventory management software enhances stock prediction, ensures optimal inventory levels, and prevents overstocking or shortages. Together, these AI-driven solutions help businesses automate workflows, minimize errors, and boost overall supply chain efficiency.

Route Optimization

Faster delivery is a concurrent need, and AI is also a winner in this. It analyzes traffic, weather, and historical route traffic patterns to suggest and help businesses with faster delivery, fuel consumption reduction, and logistics cost savings.

Compliance Management

Adhering to regulations is essential to prevent legal complications, as failing to comply can lead to reputational harm and financial penalties. AI guarantees compliance with legal and regulatory standards by streamlining documentation processes and monitoring updates to compliance requirements.

AI Applications in Supply Chain

Now that you have reviewed AI’s benefits and roles in the supply chain, it’s time to learn how AI practically helps with supply chain operations and management. Usually, supply chain tasks are redundant and require labor efforts, but AI and ML help transform traditional methods into innovative ones.

Let’s have a look!

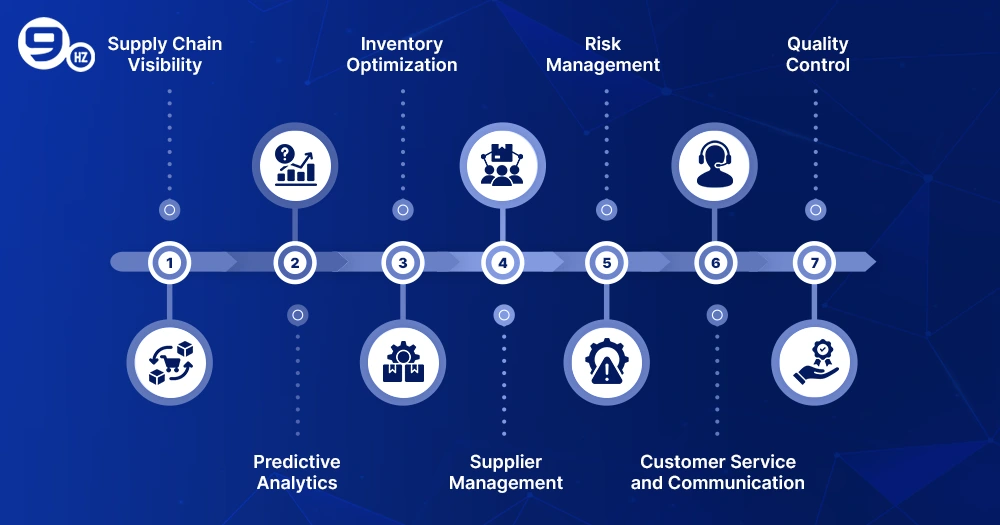

Supply Chain Visibility

Supply chain visibility creates trust among customers, and AI in the supply chain makes it real. The best combination is AI with other latest technologies, such as IoT and blockchain.

Maersk is one of the best examples of demonstrating AI for supply chain visibility. The global supply chain and logistics company uses an AI-powered platform – TradeLens, that combines Blockchain and Machine Learning for enhanced supply chain transparency and visibility. The platform tracks shipments, predicts delays, and optimizes cargo handling.

Predictive Analytics

Predictive analysis is leveraging historical and real-time data to forecast market trends, order demands, and shortages of raw materials and identify risks and issues. For example, Microsoft’s Copilot can identify supply chain issues such as natural disasters, geopolitical events, and civil clashes.

DHL, the top shipping and logistics company, leverages AI-powered predictive analytics, machine learning, and IoT to predict delays, optimize delivery routes, and improve inventory management.

Inventory Optimization

AI’s high-end demand forecasting capability empowers businesses to automate and manage inventory, identify issues, and manage stock. If you are wondering how AI-powered inventory management works, AI reads text, barcodes, and other information, enabling the warehouse management team to seamlessly manage inventory and warehouse operations.

Walmart, an American multinational retail corporation, utilizes AI in supply chain and inventory management through its AI-supply chain solution. Their AI systems analyze data from suppliers, warehouses, and stores to predict demand, optimize stock levels, and reduce out-of-stock scenarios.

Supplier Management

Supplier management is a key aspect for any business worldwide, especially for those who deal with consumer demands on a large scale, such as Amazon, Walmart, and Unilever. Here, AI-powered supply chain solutions are a savior for them.

Unilever, a British multinational consumer goods packaging company, uses an AI platform to maintain excellent supplier relationships by evaluating supplier sustainability practices and tracking compliances.

Risk Management

Identifying and mitigating potential risks and predicting equipment failures can save your business from trouble. AI can provide benefits such as proactive risk management, reduced downtime, lower maintenance expenses, and cost savings.

IBM Watson Supply Chain is one of the best examples of AI’s real-use case in the supply chain. Including supply chain management, the Watson AI analyzes risks by extracting data from multiple sources, such as news, social media, weather forecasts, etc.

Customer Service and Communication

Customer satisfaction is the ultimate goal for any business worldwide. If you are also looking for the same, AI systems for supply chain operations should be your first choice, as brands like Amazon, FedEx, and DHL use them.

Amazon, the pioneer global e-commerce company, is using AI to provide customer services and communication in the true sense. Its operations heavily rely on personalization, and AI helps understand consumer behavior, preferences, and purchase history.

Quality Control

Identifying defects and anomalies is critical for any product manufacturer, whether a beverage brand or an aerospace manufacturer. AI solves critical problems regarding quality control and improves product quality.

BMW, the world’s top car manufacturer, uses AI, machine learning, and computer vision in its assembly lines to ensure the quality of its auto parts. Using cameras and sensors ensures high-quality manufacturing that human quality analysts might miss.

AI in Supply Chain: Challenges and Solutions

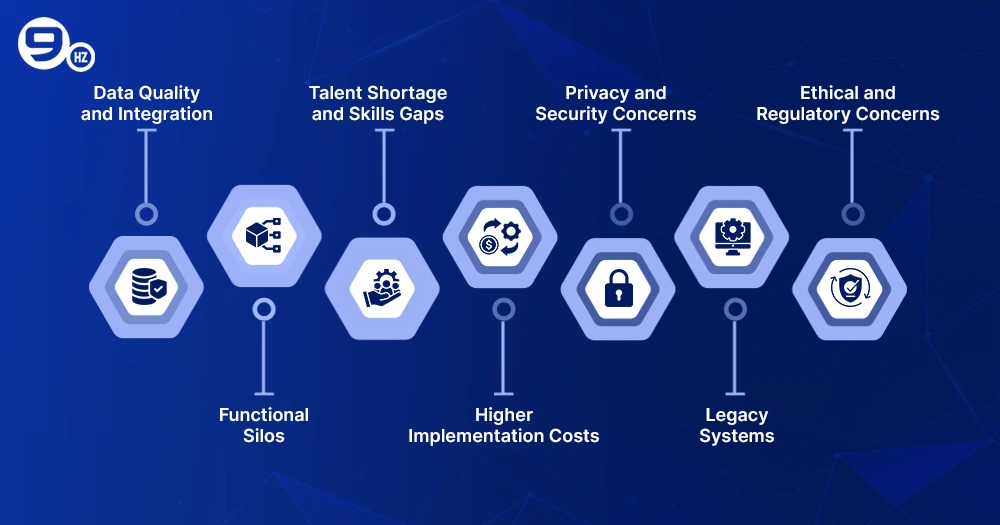

Although AI-powered supply chain solutions offer myriad benefits, specific challenges are also associated.

But no worries!

Solutions also exist, and what are these? Let’s have a look.

Data Quality and Integration

AI systems heavily rely on data, and supply chain operations generate tons of data. Poor-quality or unmanaged data from diverse sources can create a bottleneck and decrease the effectiveness of AI analysis.

Solution: Investing in data infrastructure, implementing robust data governance policies, appropriately unifying data from diverse sources, and using customized ETL pipelines(Extract, Transform, Load) to clean and standardize the data is a great solution.

Functional Silos

Functional silos are also a big challenge as teams may work isolated, and there is no collaboration between the departments for information sharing. In this scenario, things can be complicated for analysis.

Solution: The only solution to this challenge is collaboration between all departments for information sharing. You can also create a knowledge base that AI systems can access for supply chain analysis and optimization.

Talent Shortage and Skills Gaps

Fear of losing a job and lack of skills can be barriers to an organization’s implementation of AI in the supply chain. In another scenario, you have a small team of skilled experts who are not sufficient to handle the large-scale system, which is also a challenge.

Solution: The correct solution is to hire talented AI developers, upscaling your team’s strengths and bridging your team’s knowledge gap.

Higher Implementation Costs

Implementing AI in supply chains involves significant expenses. Logistics companies with minimal resources or without a suitable budget strategy may struggle to undertake this task.

Solution: list company needs, create objectives, choose essential features and schedule phases. Still, if you run across any challenges, discuss them with any seasoned AI development company for budget planning and development.

Privacy and Security Concerns

No system is safe, as cyber security risks are increasing, and AI solutions for the supply chain are no exception. The safety of crucial data and information regarding customers, suppliers, and the company is vital, but how do we safeguard it?

Solution: To mitigate risks and threats effectively, adopt cybersecurity measures, establish robust security protocols, and ensure compliance with data regulations.

Legacy Systems

Where technology is changing overnight, is using legacy systems or solutions for supply chain management good? No, not in any case, and it can be more challenging for you in the future.

Solution: The best approach is to invest in modernizing technology infrastructure and supply chain solutions. It will automatically eliminate numerous challenges and risks. You can also consult top AI development companies for greater insight on how to set up legacy modernization using AI for your business.

Ethical and Regulatory Concerns

The regulatory frameworks differ in diverse regions worldwide, and AI systems might raise challenging ethical issues.

Solution: Stay updated about regulatory changes, regular audits of AI-powered supply chain solutions to ensure compliance, and providing transparency is the only solution.

What is the Future of AI in Supply Chain?

One of the reports published by McKinsey & Company revealed that AI will transform supply chain operations entirely in the future. In another report by Exploding Topics, over 30% of supply chain professionals have already started using predictive analysis.

Another report published by an authentic source reveals that demand forecasting (35.3% share) has been dominant in applying AI in the supply chain market for the past two years. North America has also emerged as a top player using AI (37.9% share).

All these facts indicate a typical result: the future of AI in supply chain management and automation is bright.

In the context of emerging trends, these are:

- Cyber Resilient Supply Chains

- Mobile Asset Optimization

- Industry Cloud Platforms

- Smart Operations

- Actionable AI

The factors that drive the growth of Artificial Intelligence in the supply chain such as:

- Technological integration includes computer vision, blockchain, IoT, and others.

- eCommerce growth handling worldwide consumer demands.

- Resilient supply chain and risk management

- Sustainability in supply chain business and operations

- Enhanced data utilization

How Ninehertz Can Help You Build AI Solutions in Supply Chain

The NineHertz is a leading AI development company, helping supply chain businesses worldwide with their AI implementation requirements. Integrating data analytics, demand forecasting, and predictive analytics capabilities, we can help you develop AI-driven software that pinpoints your exact needs. By utilizing our skills, expertise, and capabilities, we can empower your business with better decision-making capabilities.

We provide a wide range of services, from consultation to deploying supply chain automation with AI, and what sets us apart is our years of experience in providing cost-effective solutions.

With us, you can access the knowledge base and expertise of talented AI developers for your next supply chain software development, and we ensure you deliver the best results. So, get it now from us, targeting your business’s mission-critical needs.

Conclusion

Implementing AI in the supply chain has unparalleled benefits, which is crucial in the context of its role. Supply chain operations usually occur on a large scale, with numerous associated operations. On the other hand, industry and consumer demands are skyrocketing, so you need to be resilient to handle complex tasks.

Adopting AI is perfect for your supply chain business, from improving service quality to handling challenges. AI-powered solutions will make all processes seamless, such as inventory management, warehouse automation, logistics optimization, procurement, planning, and more.

The only thing you need to take care of is to be ready with a perfect implementation strategy and a team to make it real. As a trusted AI-powered supply chain solution provider, the NineHertz is here to help you start to end, i.e., ideation to deployment. Share your needs with us and get a perfect solution today.

Frequently Asked Questions

What is AI in the supply chain?

AI in supply chain management refers to using emerging technologies such as Artificial intelligence, Machine Learning, Data Sciences, and others to perform analytics on different data sets, predict the probabilities of an outcome & actions to be taken to automate tasks for better supply chain operation.

How does AI improve supply chain operations?

AI improves supply chain operations through demand forecasting, predictive analytics, risk mitigation, error reduction, and operational cost savings.

What are some real-world applications of AI in the supply chain?

AI is used in demand forecasting, warehouse automation, risk management, inventory management, route optimization, quality control, customer relationship management, and supplier relationship management.

How does AI help with demand forecasting?

AI helps supply chain businesses forecast demand by analyzing historical and real-time sales data and market trends and predicting future demand.

How does AI improve supply chain efficiency?

AI improves supply chain efficiency in many ways, such as automating repetitive tasks, predicting stock needs, automating warehouse operations, making risk predictions, and reducing overhead costs.

What industries benefit the most from AI in the supply chain?

AI-powered solutions in the supply chain significantly benefit industries like manufacturing, logistics, eCommerce, and automotive.

Can AI optimize inventory management?

Yes, of course. Using AI, you can predict stocking needs, track and monitor concurrent stocks, prevent overstocking, and more.

How does AI enhance logistics and transportation?

AI enhances logistics and transportation through real-time route optimization, weather forecasting, and traffic analysis, reducing waste and fuel consumption.

Great Together!