Implementing a logistic management system is in vogue of late as it helps businesses transform their delivery system smoothly and rapidly. By leveraging this software, an organization can speed up its production cycle. It ultimately helps them redefine their delivery process while minimizing shipping delays.

It has fostered the need to build a logistics management system. According to the latest stats, the worldwide logistic market size was valued at $17.72 billion in 2024 and is expected to reach up to $36.26 billion by 2032, expected to grow at a CAGR of 9.36% from 2024 to 2032.

So, are you thinking about developing your logistics management solution? Your must opt forlogistics software development services. We will discuss more about how to build a logistics management system here including features and cost. So go on reading!

What Is Logistics Management System?

A logistic management Software is a type of software that can simplify various tasks such as planning, implementation, and control of logistics operations. It offers:

- Inventory Management: Keep track of stock, monitor what’s coming in and going out, and restock at the right time.

- Order Fulfillment Process: Handle orders smoothly and make sure they’re delivered on time.

- Transportation Management: Choose the best routes and manage shipping for both incoming and outgoing goods.

- Supply Chain Visibility: Stay on top of your supply chain and work better with suppliers and partners.

- Reduced Transportation Costs: Save money by avoiding delays and using resources wisely.

- Customer Service: Make customers happy with fast, accurate, and quality service.

This solution can reduce minimize manual tasks and smoothens operations by offering real-time data and automating workflow. It minimizes operational costs and enhances customer satisfaction. The software boasts numerous important features such as shipment tracking, route optimization, analytics for performance monitoring, and more.

As far as the use of logistics management solutions is concerned, it’s used widely across multiple industries. It helps businesses with many tasks, such as minimizing efforts, delivering on time, and adapting to changing market demands.

Some popular logistics management systems in the market include uRoute, eFreight Solutions, and Logistically TMS.

Tired of Managing Logistics Manually?

Streamline your operations with a smart logistics management system.

What Are the Business Benefits of Using Logistics Management Systems?

Businesses can develop a logistics management system to avail from a plethora of benefits, which helps them streamline their supply chain management system. Let’s get complete details of all those benefits below:

1. Increase Operational Efficiency

An Logistics Management Systems has an enormous capability of automating a large number of tasks to minimize any manual intervention. Automation not only saves time but also ensures operation without any errors.

It offers quick order fulfillment with a higher accuracy. An improved efficiency lets businesses allocate various resources with a proper strategy and also focus more on growth.

A logistics management system facilitate a faster order fulfillment process with a better accuracy. At the same time, the software also helps the businesses to allocate resources strategically for better productivity and drive growth.

2. Minimize Cost

When you develop a logistics management system, it minimizes your transportation time in several ways, like consolidating shipments, optimizing routes, and minimizing idle time. It also tracks several inefficiencies in supply chain processes and offers complete insight into minimizing costs.

The system also has an immense capability of minimizing inventory holding costs by offering on-time inventory replenishment.

According to mckinsey report, 50% of the US’ largest importers still use spreadsheets to manage their complex international supply chain

3. Improve Supply Chain Visibility

Be it data analytics or real-time tracking, logistic management system can improve the overall supply chain visibility. It allows businesses to analyze their inventory levels, shipments, delivery schedules, etc., in real-time. It ensures great decision-making.

It is also capable of improving transparency to minimize the overall risk of delays. It allows for smooth coordination across different supply chain nodes.

4. Boost Customer Satisfaction

Since an logistics transportation management system brings the possibility of on-time delivery with accuracy, it can directly impact customer satisfaction as well. It boasts numerous features, such as quick resolution of issues, real-time delivery updates, and more.

These are essential to enhance the overall customer experience. You need to keep in mind that satisfied customers are more likely to return, which leads to increased customer loyalty.

5. Increase Profitability

When you develop a logistics management system, it contributes a lot to increasing profitability by offering higher profit margins. It helps businesses handle a large volume of orders even without compromising on quality, increasing revenue growth, and more.

With various actionable insights, organizations can easily grab various new opportunities to increase profitability.

6. Improve Inventory Management

Effective management is highly important to balance both demand and supply. An logistics management system software offers various real-time updates on different inventory levels. It lets businesses never face situations like understock or overstock. This kind of precise control is helpful to reduce wastage, storage costs and thus increase cash flow.

Fix Key Challenges in Logistics Operations with Simple Solution

The logistics industry in the US has faced issues such as delayed delivery, rising costs, and dissatisfied customers. This happened because technology was not being utilized as much in the industry. However, with time, technology is seeping into the industry. It can solve its problems. In this section, we will explore the common logistics challenges and look at how we can solve them to make a real difference in the industry.

1. Last-Mile Delivery Issues

The logistics industry faces challenges such as urban congestion, remote delivery zones, and complex delivery routes that increase costs and lead to delays in the delivery of shipments. However, if a custom logistics management system is integrated into it, then this problem could be solved easily as the logistics management system uses last-mile delivery, which optimizes routing algorithms and GPS tracking. This technology also finds the fastest and the most efficient routes, which leads to less delivery time and operational costs. It helps drivers avoid traffic and find the fastest way to deliver packages. This saves time, reduces fuel costs, and ensures deliveries are on time.

2. Compliance with FMCSA Regulations

Logistics businesses have to face a lot of regulatory requirements from the Federal Motor Carrier Safety Administration (FMCSA). These include electronic logging device (ELD) mandates, hours-of-service (HOS) rules, and other safety standards. If the logistics business fails to comply with requirements, it will suffer heavy fines, operational disruptions, and damage to reputation. The logistics system brings transparency and automation into the system. It can monitor the driver hours in real time, and it can also report ELD. It has the capacity to integrate with the regulatory databases that can raise potential violations. All in All, it automates compliance systems, allowing businesses to focus on the other important areas of business.

3. Rising Costs

Logistics industries grapple with volatile fuel prices and labor shortages. Therefore, Providing service quality is a struggle for the businesses. However, logistics software solves this problem easily by identifying inefficiencies across the supply chain. It can suggest cost-effective routes, and it can provide suggestions for better allocation of resources. It can also predict the demand and stop the overstaffing and underutilization.

4. Lack of Real-Time Shipment Visibility

Another challenge the logistics industry has to deal with is delayed and inaccurate shipments. This issue hampers operations and reduces customers’ trust in the services and products. Since they can not track the process properly, they have to struggle to predict the issues and communicate with the people involved. However, the logistics system can address this challenge by tracking the shipments and allowing businesses to monitor their fleet and inventory in real time. It uses predictive analytics to determine potential delays before they occur.

5. Evolving Customer Expectations

Times are changing. Modern customers want to have the fastest delivery possible and accurate tracking. However, managing these activities also offers an operational cost challenge. However, the logistics system can address this challenge. It enhances the customer experience by providing precise delivery estimates, real-time order updates and different shipping options. With the help of it, customers can track their shipments easily, select convenient delivery slots, and get notifications of changes that take place in the whole supply chain. It not only builds the trust of the customers but also forms strong loyalty.

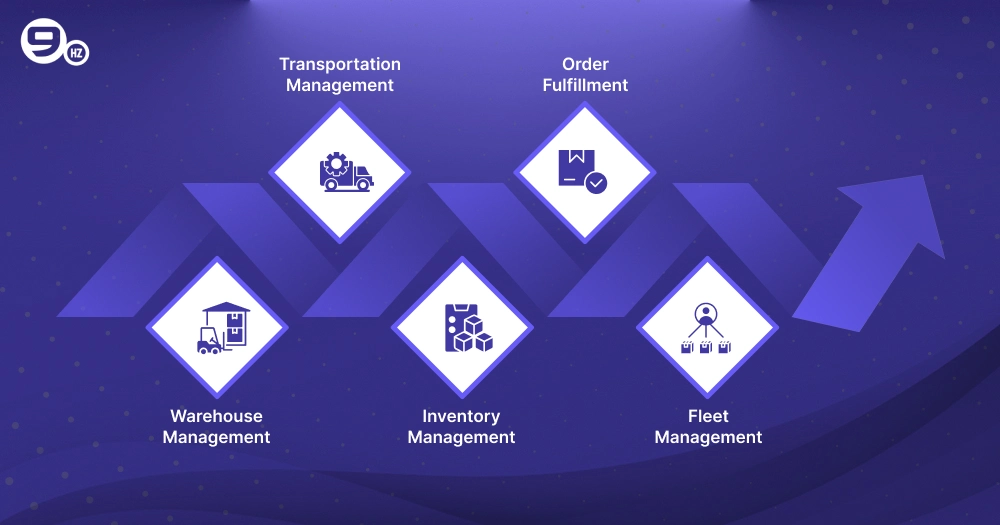

Core Components of a Logistics Management System

An logistics management solution consists of many important components. Each of these components plays an important role in the smooth functioning of logistic systems. Let’s understand these components in detail.

1. Warehouse Management

Warehouse management ensures the smooth management of different storage facilities. It lets you track and control the movement of products within warehouses, from receiving to storage and dispatch.

Its crucial features include space optimization, inventory tracking, automated order picking, and more. It ensures the storage of products and their retrievals are most efficient.

2. Inventory Management

When it comes to inventory management, it’s quite necessary to maintain an optimal stock level. It’s something that is related to tracking the location, quantity, and also status of products in real-time.

A powerful inventory management system is helpful for businesses to minimize overstock and stockouts. It also helps maintain a perfect balance between demand and supply.

3. Fleet Management

Fleet management is helpful in the efficient use of various transportation resources, including delivery vehicles and trucks. It includes various things like maintenance tracking, vehicle scheduling, driver management, and route optimization.

Its major goal is to reduce fuel consumption, minimize wear and tear, and let vehicles operate with a higher efficiency.

Fleet management is helpful in the efficient use of various transportation resources, including delivery vehicles and trucks. It includes various tasks like maintenance tracking, vehicle scheduling, driver management, and route optimization. Fleet management software development services are essential in achieving these goals by providing customized solutions that streamline fleet operations. The major goal of fleet management is to reduce fuel consumption, minimize wear and tear, and allow vehicles to operate with higher efficiency.

4. Transportation Management

This is another component that focuses on everything, be it planning, executing, or optimizing the movement of goods. It’s something that is related mainly to choosing the right modes of transportation, timely delivery, and managing carrier relationships.

Organizations can use supply chain software development services to enhance their supply chain efficiency and reduce overall transportation costs.

5. Order Fulfillment

Order fulfillment brings the possibility of processing customer orders and their delivery correctly and in a timely manner. Its process includes various things, such as receiving the order, packaging, picking the right products, and shipping them to the customer. An efficient custom order management software is important for customer satisfaction and retention.

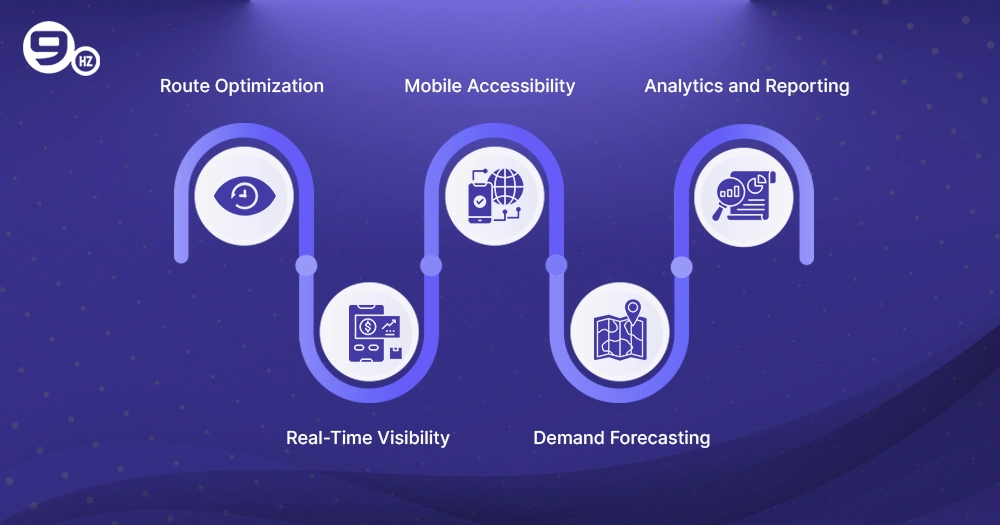

Must-Have Logistics Management Software Features

As we already mentioned above, a transport management system boasts a myriad of features that improve operational productivity and minimize costs. Following are some of the top features that logistics management system includes.

1. Route Optimization

When it comes to route optimization, it’s one of the most important and valuable features of the transport management system. It leverages algorithms for planning efficient routes for delivering vehicles or trucks.

By offering numerous factors like weather, traffic, fuel costs, delivery windows, and more. The software helps reduce overall travel time and fuel consumption. It ensures on-time delivery while minimizing operational costs.

2. Real-Time Visibility

The capability of minimizing shipments in real-time is important for businesses to manage their logistics most effectively. A transport management system can offer real-time tracking of vehicles, goods, inventory, and more.

This feature is useful for checking delays, tracking the location of assets, and offering on-time customer updates. Real-time visibility enhances customer satisfaction since clients are capable of receiving accurate delivery status updates.

3. Mobile Accessibility

As mobile technology is on the continuous rise, the transport management system also includes mobile accessibility features. It ensures logistic managers, field personnel, drivers, etc., access important information on the go.

Mobile applications can offer route updates, inventory tracking, alerts, and more. It ensures the logistic teams are in sync, irrespective of their location. This feature can enhance flexibility and streamline communication effectively across the supply chain.

4. Demand Forecasting

An logistics management solutions also includes features like demand forecasting that give it the ability to predict future logistics requirements according to market demands and historical data. It can analyze many factors, such as consumer behavior, seasonal demand fluctuations, transport management systems, historical shipment data, and more, to help businesses plan their operation perfectly. It reduces the overstock or understocking scenarios and optimizes resource allocation.

5. Analytics and Reporting

An automated logistics management system includes analytics and reporting tools that offer complete insights into operational performance. These tools can analyze different data point,s including transportation costs, delivery times, fuel consumption, inventory levels, and more.

By producing reports, the software allows logistic managers to analyze performance, find inefficiencies, and make decisions based on the data. It indeed enhances overall logistic operations.

Tech Stack Needed for Developing a Logistics Management System

Developers need to leverage many tech stacks to build a logistics management system. It ensures the efficiency, scalability, and security of the entire system. Let’s explore all those tech stacks in detail.

1. Front End Development

The front end offers a complete, user-friendly interface for many drivers, customers, admins, and more. Frameworks such as Angular or React.js provide responsive and dynamic interfaces.

Vue.js is also best for lightweight and simple options. These frameworks allow smooth user interactions, which is important for tracking shipments, managing orders, and communicating in rreal time

2. Backend Development

As far as the backend is concerned, it can handle data processing, business logic, user authentication, and more. Many popular technologies like Node.js with Express for JavaScript-based development or Flask and Django in Python.

Ruby on Rails (RoR) is a perfect choice for quick development. The back end is capable of handling many tasks including managing inventories, calculating logistic routes, and processing transactions.

3. Database Management

It’s important to manage vast datasets, including user information shipment details, and inventory. Many Relational databases including MySQL or PostgreSQL are a top choice when it comes to structured data.

On the other hand, NoSQL databases, including MongoDB, are a perfect choice for unstructured or semi-structured data. Redis is a perfect choice for caching to improve the overall system performance.

4. APIs

Proper integration with many third-party services like mapping services, payment gateways, GPS tracking systems, and more is necessary. GraphQL and RESTful APIs are used mainly to facilitate smooth data exchange between front, back, and external services.

5. Cloud Services

Be it is Google Cloud, AWS, or Microsoft Azure, many cloud service providers host the transport management system. They promise to offer security, scalability, performance optimization, and more. These platforms also provide ML and analytics tools for enhancing forecasting and thus the decision-making process.

6. Security

When it comes to system integrity and data protection, these are indeed highly important. It includes many security features like SSL/TLS encryption for secure communication. JWT or OAuth for user authentication. A Firewall and intrusion detection systems can safeguard the platform against many cyber threats.

Simplify Your Logistics Today!

Optimize deliveries and reduce costs with our easy-to-use system

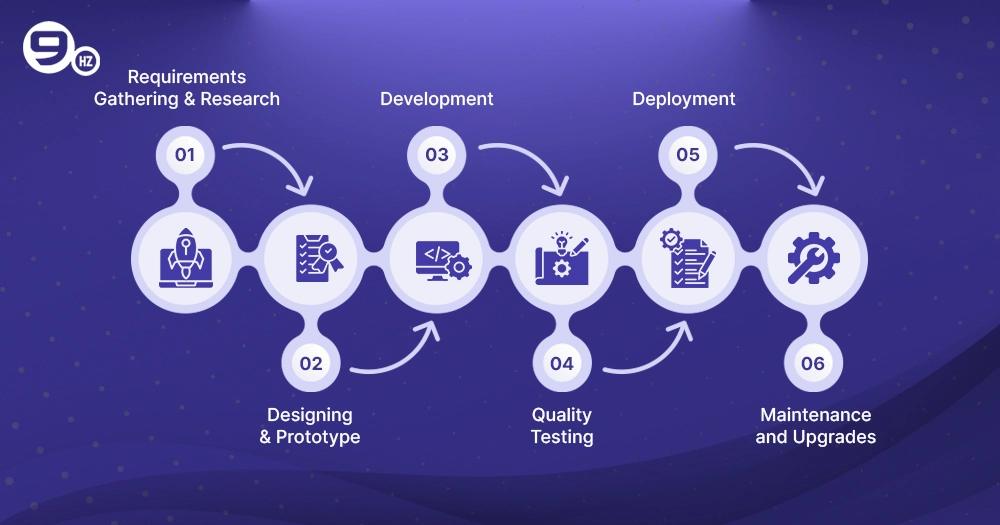

How to Build a Logistics Management System?: Step-by-Step Process

When it comes to building a logistics management system, it’s something that involves a fully structured approach and also involves numerous steps. We will discuss each step in detail.

1. Requirements Gathering

The first step to building a logistics management system is to gather the requirements. The development team needs to find complete details related to specific business requirements, inventory management, shipment tracking, and more.

2. Designing

You can craft a user-friendly interface and a powerful system architecture. The step involves creating wireframes and prototypes to visualize the complete layout and workflow of the desired logistics management system software.

The logistics software development team plans the database for the storage of logistic data with proper security and considers the integration of APIs for many third-party services, including payment gateways and GPS tracking.

3. Development

After finalization of the design, it’s time to build a logistics management system by implementing the agile methodologies. Developers create core modules, including route optimization, order processing, customer management, and more. They focus on both scalability and performance when it comes to handling the increasing operational demands.

4. Testing

Testing is quite essential to identify and resolve issues with proper measures. The logistics software development team performs different tests, including integration, functional, and performance testings, to ensure the software operates well. The team also gathers end users’ feedback during this phase, which helps refine the overall system further.

5. Deployment

This step is all about the launch of the transport management system on the desired platform, be it cloud-based or on-premise. You need to ensure proper data migration and also conduct a pilot run to find out any issues. It’s also necessary to provide training to users for a smooth adoption.

6. Maintenance and Upgrades

After the final deployment, you can analyze the overall performance of the system and also address the necessary issues quickly. You can roll out various periodic updates to incorporate many new features, improve security, and adapt to the changing business needs.

Costs Involved in Building a Logistics Management System

Cost to build a logistics software depends on numerous factors. These include technology stack, project complexity, business requirements, and more. Let’s grasp this in detail.

| Step | Overview | Cost |

|---|---|---|

| Development | The logistics software development cost can vary based on several things such as location, team expertise, and the overall required time for completion of the project. | On average, the development cost ranges from $30,000 to $200,000. |

| Infrastructure | To build a logistics management system, you need to develop infrastructure. It involves leveraging cloud platforms like Microsoft Azure or AWS. These are available with flexible pricing. | Its average cost is $100 per month for those small-scale systems. |

| Designing | Designing a transport management system is about crafting UI/UX design. | It ranges from $6,000 to $20,000. It depends on several factors, including the complexity of the design. |

| Integration | Integration of many third-party APIs, including payment gateways, GPS tracking, or ERP systems, also involves additional cost. | Its cost ranges from $6,000 to $15,000. |

| Maintenance and Updates | Be it post-launch, regular updates, or maintenance, these are necessary. | It involves an overall cost of 15 to 20% of the overall development cost per year. |

Examples of Successful Logistics Management System Software Implementations

To understand the transport management system, you need to understand several examples as well. Let’s explore some of the top examples of logistics management system implementations here.

1. Amazon

Amazon is one of those companies that leverage the vast potential of logistic management systems efficiently. It integrates warehouse operations, inventory management, and last-mile delivery properly.

Some of its top features, including real-time tracking and predictive analytics, ensure the organization guarantees quick delivery and provides services, including Prime. Apart from this, the use of robotics in fulfillment centers increases the speed and accuracy of order processing.

2. DHL

DHL is another company that has implemented logistics management software solutions successfully and thus improves its operation across the globe. It has incorporated AI and IoT sensors, predicts maintenance requirements, analyzes fleet performance, and can track shipments in real-time. Its automation capabilities have minimized manual errors and boosted customer satisfaction.

3. Walmart

Walmart uses a fully sophisticated logistics system to manage its supply chain. It has implemented cross-docking practices, which leads to reduced overall storage costs and can improve the speed of inventory turnover.

Many cutting-edge technologies incorporated into its LMS ensure smooth communication between different distribution centers, suppliers, retail outlets, and more.

4. Maersk

Being one of the most well-established names in global shipping, it completely leverages the potential advantages of Blockchain technology within its transport management system. This innovative LMS offers end-to-end transparency across the supply chain. It increases efficiency and minimizes paperwork.

5. Zara

Being one of the top fashion brands, Zara uses logistics management solutions designed exclusively for fashion models. It supports various things like real-time inventory updates and ensures efficient distribution to stores across the world. Its fast response allows Zara to maintain a competitive edge in the retail industry.

Businesses Without vs. Businesses Using an Logistics Management Solutions

In today’s business atmosphere, continuous learning and development are of great importance to stay competitive. So, the choice between managing training manually or adopting a learning management system is something that can certainly impact the growth and efficiency of business. Let’s have a detailed comparison to define the actual differences.

1. Efficiency in Training Delivery

Without

Businesses that rely on traditional methods often face various logistic challenges when organizing training sessions. Be it venue booking, scheduling, or manual attendance, these are indeed time-consuming and cause inefficiencies.

With

An logistics management system can automate these processes effectively. It enables training to be delivered digitally. Employees find it convenient to access materials anywhere, anytime, which minimizes downtime and also ensures a smooth learning experience.

2. Customization and Scalability

Without

When it comes to training, individual requirements are indeed quite stringent, especially without a centralized system. With the growth of the workforce, the ability to manage diverse training requirements manually becomes indeed unmanageable.

With

A transport management system creates customizable learning paths which cater to different roles and skills levels. It can scale properly for the accommodation of many users, which ensures smooth growth in training programs.

3. Tracking and Reporting

Without

Monitoring performance and employee progress causes errors as well. Many reports are often incomplete, which makes it complex to assess training effectiveness.

With

An logistics management software provides real-time tracking and also in-depth analytics. Managers can easily analyze progress, identify knowledge gaps, and make decisions based on data. It improves training outcomes as well.

4. Employee Engagement

Without

One-size-fits-all training is something that quite often fails to engage with many employees, which causes mainly poor retention of skills and knowledge.

With

Many interactive features such as multimedia content, gamification, quizzes, and more ensure a proper engagement of employees. It ensures great learning outcomes.

AI in Logistics Management Systems

Artificial Intelligence (AI) has taken the transport management system to the next level by increasing accuracy, efficiency, and cost-effectiveness. Many AI-driven tools are capable of optimizing route planning, which ensures on-time delivery and minimizes overall fuel consumption. Let’s understand the overall impact of AI in logistic management systems.

- Predictive analytics ensure demand forecasting, supply chain resilience, and inventory management by tracking out some potential disruptions.

- Machine learning algorithms are capable of automating warehouse operations, including packing, sorting, inventory tracking, and limiting human error.

- AI-powered chatbots can enhance customer service by offering real-time shipment updates and also can resolve queries quickly.

- AI improves the decision-making process with actionable insights from huge data sets, streamlines operations, etc.

- With the implementation of Artificial Intelligence, logistics businesses can achieve increased productivity, operational agility and gain a competitive advantage.

Struggling with Logistics Chaos?

Get a tailored solution to manage your supply chain smoothly

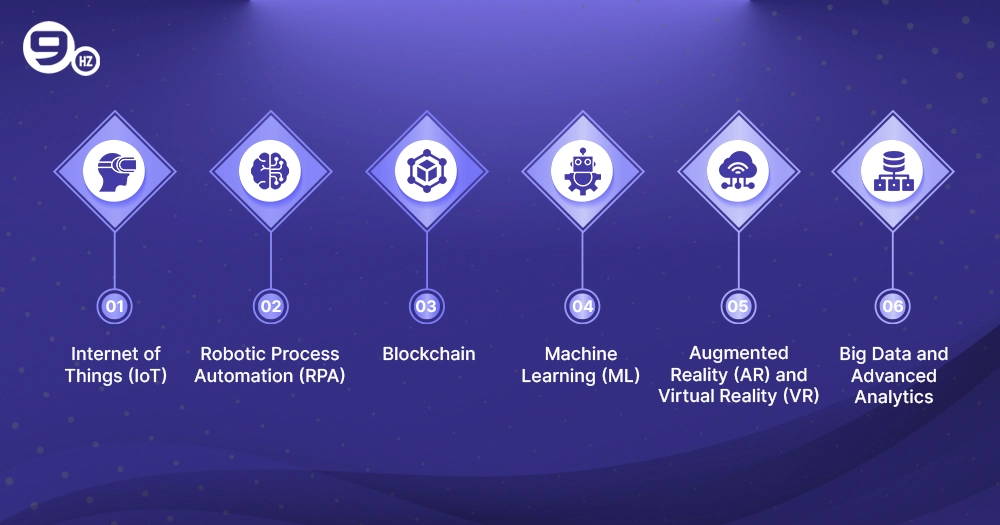

Top Trends Businesses Look for in a Logistics Management System in 2024

Many emerging technologies have reshaped the future of transport management systems by making them more advanced and business-centric. Let’s understand all these future trends in detail.

1. Internet of Things (IoT)

IoT has transformed logistics with sensors and smart devices that allow real-time tracking of assets and shipments. Many IoT devices can determine environmental conditions by analyzing the parameters such as humidity and temperature. It secures sensitive products such as perishable food as well as pharmaceuticals.

Many IoT-based predictive maintenance can decrease equipment downtime, enhance overall operational efficiency, etc. Furthermore, the Internet of Things technology makes fleet management more efficient through the provision of valuable data on drivers’ behavior, fuel consumption, vehicle health, and more.

2. Robotic Process Automation (RPA)

RPA can automate many time-consuming and repetitive tasks, including order processing, data entry, invoicing, and more. It results in decreased productivity and human error. Robots can improve warehouse processes such as shipping and packaging, which in turn would lead to lower costs for labor and increased throughput.

RPA can also ensure smooth communication between varied transport management systems, which offers smooth coordination. It also ensures a complete data flow across different supply chains.

3. Blockchain

Blockchain technology provides a general security and transparency boost in logistics through the recording of immutable shipments and switching all of the records to a cloud-decentralized system.

Besides, the use of smart contracts can facilitate smoother processes such as customs clearance and payments, thus resulting in reduced paperwork and reduction of delays.

Blockchain reduces fraud by guaranteeing the integrity of products through end-to-end traceability. This practice has proved to be the most important in several sectors.

4. Machine Learning (ML)

When it comes to ML algorithms, they can analyze historical data to uncover many trends and patterns. It ensures perfect forecasting and decision-making. ML models can easily predict delivery delays caused by traffic, weather, or also other disruptions.

It offers various proactive measures. ML ensures a dynamic pricing model, which helps businesses optimize costs based on demands.

5. Augmented Reality (AR) and Virtual Reality (VR)

AR/VR are two additional ways that have become a great contribution to day-to-day training in facilities and warehouses. AR (Augmented Reality) tools can assist these employees in the work, as they have the option of projecting digital information in real-world situations, which enables workers to locate and pick objects easily and quickly.

By using virtual reality, workplaces present immersive training to their employees, which creates a safer environment and minimizes the number of mistakes. These technologies are capable of giving that kind of experience to the customer by enabling them to view the virtual representation of the shipment, packing, and handling of it.

6. Big Data and Advanced Analytics

When it comes to Big Data plays a vital role in modern logistics. It allows organizations to harness huge amounts of details to optimize operations. Robust analytics tools can process data from multiple sources to offer complete, actionable insights into supply chain performance, market trends, and customer behavior.

Predictive analytics can easily identify many potential risks, including route disruptions, equipment failures, etc., which ensures on-time interventions.

How The Ninehertz Can Help You Solve Your Logistics Challenges with a Custom Logistics Management System?

The Ninehertz, a Custom Software Development services can help you solve your logistics challenges by creating a custom logistics management system tailored to your specific business needs. Here’s how:

- A custom system brings all your logistics tasks—like tracking shipments, managing inventory, and scheduling deliveries—into one easy-to-use platform. This saves time and reduces errors.

- You’ll always know where your shipments are, thanks to real-time tracking. This improves transparency and helps you respond quickly to any delays.

- By optimizing routes, reducing paperwork, and automating repetitive tasks, a custom system can lower your overall logistics costs.

- Faster deliveries and better communication with your customers mean happier clients and repeat business.

- As your business grows, the system can adapt to handle more orders, customers, and delivery points.

At The NineHertz, we don’t just build software—we build solutions that work for you. Our team partners with you to deeply understand your business challenges and deliver a customized system that ensures a smoother, more efficient logistics process. Let’s turn your logistics into a competitive advantage.

Conclusion

So, after going through the above discussion, you may now have enough information regarding the process to build a logistics management system. It’s time now to start your journey to build a logistics management system.

Before you proceed, you can focus on your important business requirements, key objectives, operations, and more. It helps you plan well and proceed accordingly. Hiring an experienced transport management system development partner will help you achieve your goal.

Frequently Asked Questions (FAQs)

1. How Long Does It Take to Build a Logistics Management System?

Well, creating a logistic management system generally takes 3 to even 12 months. The overall time depends on several factors, such as features, complexity, integration requirements, and more. To build a logistics management system with standard features and functionalities that can be completed within 3 to 6 months.

Meanwhile, the development of advanced solutions with advanced features and functionalities may take up to even a year.

2. What Is the Cost of A Custom Logistics Management System?

The average cost of building a logistics management system with custom features may range from $ 30,000 to $200,000 or even more. It depends on many factors, such as complexity, features, scale, and more. When you build a logistics management system with limited and basic features, it can be cheaper, whereas the development of advanced systems with robust features can be expensive.

3. Can an Logistics Management System Integrate with Existing Software?

Yes, an logistics management system can be integrated with the existing software. A large number of platforms can support integration with numerous tools like HRMS, CRM, content management systems, video conferencing apps, and more. It ensures a smooth data exchange, enhances workflow efficiency, and offers a complete unified experience. It improves organizational performance as well.

4. What Industries Benefit the Most from An Logistics Management Solutions?

Many industries can benefit from an logistics management solution. Some of these industries are education, healthcare, retail, corporate training, technology, and more. These sectors leverage logistics transportation management system to streamline compliance training, employee onboarding, skill development, continuous education, and more. It improves efficiency, ensures consistency, minimizes costs, etc.

5. Why Should Businesses Invest in An Logistics Management Solutions?

Businesses should invest in an logistics management system to improve and streamline onboarding and employee training and ensure highly consistent skill development. A transport management system can enhance productivity by offering convenient access to tracking progress and learning resources and providing personalized learning paths. It also minimizes overall training costs, supports compliance, and enhances employee engagement. It boosts both the growth and performance of the business.

6. How can AI improve a Logistics Management System?

AI can boost logistics management software in several ways, such as enhancing inventory management, optimizing route planning, predicting demand, and more. ML algorithms can analyze real-time data to boost delivery efficiency, reduce risks, minimize costs, etc. AI-driven tools can improve warehouse operations, customer service, automated tracking, and more.

7. What Industries Require Specialized Logistics Management System Features?

Many industries like manufacturing, education, healthcare, and others need compliance-driven sectors that need specialized features. You need to keep in mind that healthcare requires HIPAA-compliant training and continuous certification training. The education industry needs personalized learning paths and assessments.

Great Together!