- Construction teams are implementing AI to build better projects, anticipate potential delays early, control costs, improve safety, and manage resources more efficiently from inception to completion.

- Studies show AI can boost productivity by up to 15% and cut upfront costs by 6%.

- The AI in construction market is expanding by almost 27% annually, and small- and mid-size contractors are increasingly relying on cloud-based AI solutions to stay competitive.

- AI is already enabling site teams to better plan and improve labor efficiency, helping save time and mitigate risk on a daily basis through predictive analytics, safety tracking, material planning, and workforce management.

- Companies that begin with small pilots, organize their data, train their people, and work with the right artificial Intelligence development services partners see faster returns.

Artificial Intelligence (AI) is booming, and every industry is undergoing a significant transformation, where the construction industry is no exception.

Though AI in construction sounds like a “not-so-important” factor, it has major use cases that benefit both firms and employees.

Before we dive into the answer to How to use AI in construction, let’s understand a quick overview of its significance.

Speaking of the facts, the engineering and construction (E & C) industry is worth more than $10 trillion a year, according to McKinsey reports. (Source: McKinsey).

Implementing AI can help construction firms to create visually stunning yet practical designs, schedule projects, manage suppliers, and monitor costs. On the other hand, it allows workers increase productivity while maintaining their safety.

Recently, McKinsey did some astonishing research on AI in the construction industry, and the results were shocking. They realized that AI in construction could deliver up to 15% in productivity gains and reduce upfront expenses by up to 6%, ultimately saving trillions of dollars. (Source: Reports and Data).

Sounds surprising, doesn’t it!

The growth of AI is driven by a multitude of factors, including the mushrooming demand for automation in construction processes, project management tools, and a focus on reducing site risk.

Now, the question is- What are the AI applications in construction industry? What are the best AI tools to use in construction? Is there any future for AI in this industry?

Without further ado, let’s dive into the complete guide to AI in the construction industry!

What Is AI in Construction?

To put it simply, AI in construction refers to the use of AI technologies, from machine learning to robotics, in the construction industry. Whether you are planning to automate a process, design a plan, or facilitate quick decision-making, these systems are a viable choice.

Construction companies are leveraging emerging technologies to manage these projects efficiently and reduce the risk.

For example, if a construction firm implements an AI chatbot, it may save time on a basic task, while incorporating predictive analysis (another subset of AI) may help save $5 million by recommending changes to a project.

Sounds surprising, doesn’t it!

Yet the diffusion of AI was not immediate. Ongoing national-level structural and operational pressures also fuel it. Listed below are some essential reasons for using AI in construction.

- Workforce Shortage

- Schedule Overruns

- Rising Material Costs

Due to labor shortages, AI has been deployed to handle monotonous scheduling, reporting, and inspections.

Such overruns are inevitable. Thus, predictive analytics identifies delays before they occur, enabling supervisors to adjust resources dynamically.

For example, AI on construction sites can assist project managers in comparing service costs from various providers to reduce waste.

AI in Construction: Market Size & Adoption

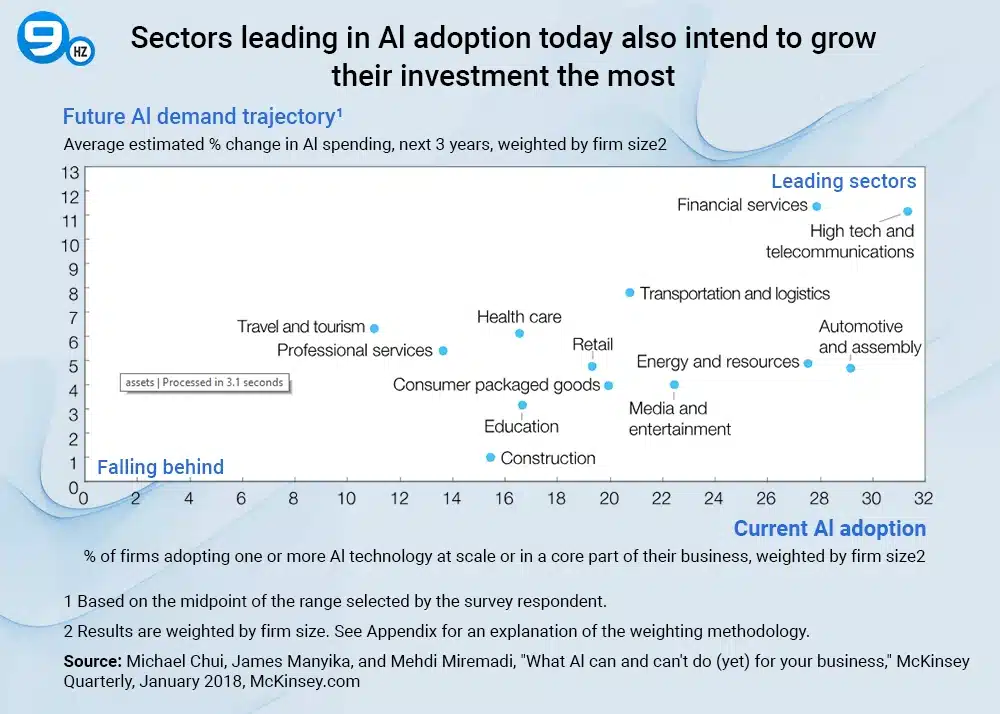

AI use cases in manufacturing are increasing rapidly. The growth of this field is driven by several benefits, including cost overrun prevention, operational efficiency, and budgetary control. But let’s first take a very brief overview of the construction market and AI adoption.

- The Artificial Intelligence in Construction market will reach a total global market value of USD 16.96 billion by 2030, with a CAGR of 26.9%.

- 89% of construction and engineering executives said AI adoption improved profitability (2025 global survey).

- Middle East & Africa AI in the construction market is planning to establish a dominant market foothold, with a CAGR of 30.1% from 2024 to 2030.

- Small & Medium-sized Enterprises (SMEs) organization segment is all set to increase with a CAGR of 28.3% from 2024 to 2030.

| Market size value in 2024 | USD 4.06 billion |

| Revenue forecast in 2030 | USD 16.96 billion |

| Growth rate | CAGR of 26.9% from 2024 to 2030 |

| Projected 2032 market size | USD 22.68 billion |

| Regional scope | North America, Europe, Asia Pacific, Latin America, MEA |

What are the 5 Key Benefits of AI in Construction?

There are numerous benefits of AI in construction, including increased efficiency and reduced costs. We’ve compiled a list of the top 5 key benefits of AI applications in construction industry.

1. Improves Project Planning

Project teams typically have incomplete data, congested timelines, and are almost always in a state of constant change. The AI analyzes both historical and ongoing project data, which may help construction companies easily identify conflicts, budget risks or design issues. Therefore, better decisions may ultimately result in more predictable project outcomes.

2. Reduces Costs & Prevents Rework

Unexpected errors and changes in the construction project can significantly raise the overall costs. AI tools read blueprints, designs, schedules, and material use to spot the mistakes before they are built. Problems of incompatible design can be identified before moving forward, mistaken estimates can be realized more rapidly, and sequencing errors become easier to detect early. Consequently, reducing unplanned circumstances in construction will lower rework costs, which helps manage project budgets.

3. Boosts Productivity

Productivity among construction teams is very low due to recurring manual tasks such as checking progress, updating schedules, and handling paperwork. AI use in construction eliminates most of these repetitive activities and ensures that all information is always up to date. Therefore, it ultimately increases overall productivity without increasing labor inputs.

4. Enhances Safety and Risk Management

Safety on construction sites remains a challenging issue. This is where we use AI! From images and video to processing data, AI helps recognize vulnerable conditions by identifying unsafe site layouts. Furthermore, with early warnings, supervision can step in before an accident occurs. Better safety conditions also protect workers, ultimately helping a construction company avoid cost overruns, insurance claims, or lawsuits.

5. Supports Predictive Maintenance and Asset Performance

Downtime is generally expensive due to equipment and building system failures. AI use in construction helps monitor data streams related to machine and infrastructure performance to predict when they might be worn out or failing. Furthermore, all alerts are sent to standardized maintenance teams, which can solve the problem even before the failure occurs. High-quality equipment is less likely to fail, and lab projects will not lag behind.

20 Practical Ways to Use AI in the Construction Industry

1) AI Dash Cams Integration for Fleet & Site Safety

Distracted driving and a lack of visibility into driver behaviour are contributing to higher-than-average accident rates. Companies like Ernst Concrete, a trucking company, have begun using AI dashcams, such as those made by Lytx, to track driving events and provide real-time feedback and driver training. After implementing the solution, Ernst Concrete reduced driving while talking on a cell phone by 97%, distracted driving by 83%, and close-following incidents by 81%, vastly improving safety while reducing insurance costs.

2) Collaborative AI-Based Budget Planning

Budget overruns occur because teams use disconnected spreadsheets and outdated assumptions. Procore and Autodesk Construction Cloud, for instance, are using AI within large companies to consolidate cost data, schedules, and risk scenarios into a single platform. Those who employed budgeting with AI reported 20% improved accuracy in cost estimates; nearly 15% less time in preconstruction-phase planning; fewer surprises partway through the project when budgeting.

3) Financial Management & Expense Forecasting

It is difficult for construction companies to predict costs over long project horizons. Companies employing AI for financial forecasting on platforms like Oracle Construction Intelligence Cloud can model historical spend and real-time project data. Oracle states that AI-based forecasting delivers 40% better cost predictability, enabling firms to protect margins and improve cash flow.

4) AI-Powered Material Processing Optimization

The team can misjudge quantity and timing, resulting in material waste. Firms such as Skanska and Bouygues Construction use AI tools that can analyze drawings as well as historical data to improve material processing and ordering. Industry reports suggest that AI has the potential to cut material waste by 25%, thereby reducing disposal costs and preventing project schedule delays.

5) Reducing Cost Overruns Using Predictive Analytics

Projects are already committed at this point: cost overruns are frequent because risks are discovered so late that little can be done to rectify them. Global contractors like Skanska and Bechtel are using predictive analytics to identify project schedule or cost risks earlier. According to McKinsey, predictive analytics can reduce cost overruns by 40% and significantly improve on-time project delivery.

6) AI for Emissions Monitoring in Construction Projects

Construction firms must limit carbon emissions with limited real-time monitoring. AECOM, for example, uses artificial intelligence sensors that continuously monitor fuel consumption and equipment emissions. These AI applications in the construction industry have helped companies reduce carbon output by 15-30% while meeting sustainability objectives.

7) AI-Driven Payroll and Workforce Analytics

Big job sites experience low productivity levels due to payroll glitches and misallocation of labour. Fluor Corporation, for example, employs AI workforce analytics to pair skills with functions and predict staffing requirements. According to Fluor, productivity has increased by more than 12%, and employee satisfaction has risen along with rate control.

8) Expense Tracking and Anomaly Detection

If there are upfront expenses, a project can become unprofitable. Businesses using AI-powered finance can monitor transactions in real time to identify anomalies. For example, AI-driven expense tracking reduces financial leakage by 18-30% and makes it easier for teams to catch fraud sooner.

9) Real-Time Site Safety Monitoring

A manual site-safety checklist cannot prevent or even identify dangerous conditions over a large site. AI computer-vision platforms like Visionify are also being used by contractors to track live data on PPE usage and unsafe behaviors. According to Visionify case studies, companies reported reductions of up to 78% in safety incidents.

10) Inventory Management and Procurement Optimization

Construction is also often delayed by a lack of available materials or overstock. Companies that deploy AI use cases in construction to forecast demand will also adopt procurement systems based on actual consumption at a specific site. Artificial intelligence-based inventory optimisation reduces storage expenses by 30% and eliminates downtime caused by missing materials.

11) Fraud Detection in Construction

Construction companies are losing millions of dollars a year to invoice fraud and billing manipulation. This is where AI comes in! Implementing AI systems helps detect and highlight suspicious spending and vendor activity patterns. Research has shown that AI systems that can identify fraud have led to a 20-35% decrease in financial losses, helping ensure greater compliance and trust.

12) Project Performance Tracking

The project managers do not have a real-time view of the project’s status. Firms that build on platforms such as Procore and use AI dashboards can continually monitor live cost, schedule, and risk indicators. According to industry benchmarks, projects that incorporate AI performance tracking experience a 35- 55% bump in on-time delivery.

13) Automated Workforce Training Programs

Traditional training programs do not account for the wide range of skill gaps among individuals. Other studies have pointed to AI-based training platforms, which adjust their teaching methods to each individual’s new hire’s work performance. “AI-training” companies increased compliance and skills readiness by as much as 22%, leading to fewer on-site errors.

14) AI-Based Report Generation

Project teams waste hours preparing manual reports. Platforms such as Procore Copilot automatically generate project summaries using AI. By using AI reporting, contractors’ reporting times have been cut by 12-30%, freeing up managers to make decisions.

15) Workflow Optimization Across Departments

Fragmented workflows also limit cross-team collaboration. AI analyzes dependencies between tasks and reveals bottlenecks among departments. AI-enhanced work processes improved productivity by about 20% for construction companies, and the adjusting process has quickened project delivery.

16) Quality Control Using Computer Vision

People can’t notice the flaws in the fast building process. AI computer vision capability enables companies to scrutinize images for variations in design specifications. Quality control is improved by over 40% through AI-driven defect reduction, and rework costs are drastically reduced.

17) AI-Powered Construction Project Management

Complexity is a challenge for traditional project management tools. AI-based project management platforms enable contractors to change schedules and resources on the fly. Companies using AI in construction reduce project delays by 10-23% and achieve higher delivery performance.

18) Smart Technician Scheduling & Routing

Bad routing is simply a waste of labor hours and fuel. Technicians’ availability is pre-determined by AI scheduling tools that take into account individual skills, location, and traffic conditions. Companies that have implemented AI routing can cut travel time by 15-25%, leading to more productive working hours.

19) AI in Construction Equipment Maintenance & Utilization

Idle equipment drives unnecessary costs. Construction companies also employ AI to monitor usage and predict when equipment needs maintenance. The “smart” systems deployed as part of AI solutions in practice also reduce downtime by 15-25%, thereby increasing asset lifespans.

20) Predictive Delay & Risk Alerts

Time to detection also increases, as the team takes longer to identify a risk. With AI use in construction, companies can analyse schedules, weather, and labour data to forecast delays accurately in advance. Predictive alerts help prevent unexpected delays, improving them by 38%.

What Are the Key AI Features in Construction Management Software?

The AI has revolutionized construction management software, transforming raw project data into actionable insights. By 2026, construction workers can count on AI to make decisions more intelligently, reduce risks, and deliver projects on time and within budget. These features enable decision-making at each level of a construction project, from pre-construction planning to site design and post-construction analysis.

1. Predictive Project Scheduling

AI converts project data, weather, and workforce to realistic schedules. It also records changes and delays so that team members are on track, and it is able to alert workers on time to avoid last-minute surprises.

2. Intelligent Cost Estimation & Budget Control

AI-powered systems can generate reliable cost estimates based on historical information and current market conditions. They follow spending over time and alert managers if budgets may go over estimated amounts as the project progresses.

3. Real-Time Risk & Delay Detection

AI checks vendor performance, material delivery and site activities for potential risk. Furthermore, it detects scheduling problems to prevent their escalation.

4. Computer Vision for Site Monitoring

Using AI-powered cameras and drones helps track construction progress, locate broken equipment, and detect theft. Thus, it allows for fewer manual inspections and provides more visibility for remote stakeholders.

5. Resource & Equipment Optimization

AI monitors the labor, equipment, and materials used in any project. It encourages resource use to reduce downtime, shortages, and productivity.

6. Automated Safety Monitoring

AI systems can detect unsafe behavior, missing safety gear, or dangerous conditions in real time. Alerts help supervisors stay immediately aware of accidents and safety procedures.

What are the Challenges of AI in Construction Management?

1. Limited Adoption & Slow Scaling Across Projects

The construction industry has yet to realise many of these AI aspirations because most construction companies don’t know where to start or don’t see the business value. A global RICS survey of over 2,000 construction professionals found that approximately 45% of companies have no AI applications and only 12% use AI frequently in specific processes; a mere 1.5% stated that they were broadly using AI in their organizations.

Another industry leader, Shawmut Design and Construction, has utilized AI to make building sites safer for construction workers. Still, the non-linear incorporation of technology continues due to the fragmented nature of the technology and the lack of ‘clear returns on investments’ for many of the tools.

2. Shortage of Skilled AI and Data Experts

Workers lack the expertise to install and maintain AI systems. Nearly 46% of industry respondents answered that the scarcity of skilled people is one of the main obstacles to AI implementation. Companies such as Bechtel addressed this by investing in training programs that raised workforce proficiency by an estimated 30%, but smaller contractors don’t have the luxury of long training cycles or AI expert jobs to hire.

3. Integration with Legacy Systems & Poor Data Quality

AI solutions typically require high-quality, logically structured information, as well as the ability to integrate with existing software, something many construction companies lack because they either have outdated systems or disconnected databases. Emails, spreadsheets, and project systems are integrated, but the data remains isolated across them, leading to AI output errors & necessitating attempts to bring them together.

As one study indicates, 37% of construction professionals believe integration concerns remain a primary obstacle to a successful rollout of AI.

4. High Investment Cost & Unclear ROI

The costs of AI in construction include sensors, cloud platforms, training, and support, which must be incurred in advance, while the benefits are often uncertain or out of firms’ view. These reports suggest the involvement cost is prohibitively high, especially for smaller contractors who are discouraged by high license fees or upfront hardware purchases. Even firms as large as Clark Construction prefer a phased AI deployment, such as adopting an AI-cloud combo that can cut processing time in half, because they cannot afford to experiment with large-scale projects and expect quick results.

5. Trust, Accuracy, and Reliability Concerns

Sometimes, the outputs of AI models may not fully align with real-world construction problems, or they may be incorrect. When building large language models and predictive systems, unless highly domain-specific data is used to train them, one risks those systems hallucinating or losing important engineering details. It has caused several C-level executives to become skeptical of announcements saying AI is taking over, despite strong overall interest in AI among companies.

2 Real-World Examples of AI in Construction Projects

Artificial intelligence is no longer a novel concept as business giants and industry leaders worldwide are already leveraging this technology to streamline their operations and embrace competitive advantages. Here are some AI in construction case studies showcasing popular firms using Industry 4.0 technologies to automate their workflow.

1) Caterpillar Uses AI and Autonomy to Streamline Heavy Equipment Operations

Caterpillar had concerns over the cost of equipment downtimes and safety risks on large job sites. Multi-purpose traditional maintenance errors hampered progress and lower operating costs. Caterpillar, for example, partnered with Nvidia to integrate AI and autonomy “at the machine,” in its heavy equipment, including excavators, dozers, loaders, and haul trucks. Their new Cat AI Assistant provides voice-activated assistance to operators, which enables semiautonomous operation. Such technology can also use real-time data to predict when machinery needs maintenance, helping prevent breakdowns and keep machines running longer. These AI initiatives have enabled Caterpillar to improve construction efficiency, safety, and overall productivity.

- Caterpillar has also incorporated AI into its heavy machines to reduce downtime.

- AI to prevent costly breakdowns.

- Increased safety and efficiency through greater operator support.

2) Bouygues Construction Uses AI to Reduce Material Waste and Optimize Schedules

Bouygues Construction struggled with material waste and the complexity of schedules associated with its use of large infrastructure projects. The limitation was that with more traditional design processes, it was challenging to make a structural evaluation of various build-up scenarios early on. Bouygues has addressed this problem by using AI platforms that assist engineers in testing multiple design and construction processes before work commences. On the Bagneux metro station project in Paris, AI-based architecture transformed a retaining wall. This has eliminated 140 tons of steel and both costs and environmental consequences. Bouygues also utilizes scheduling AI, which simulates build sequences for different crew sizes and resource plans, to help teams “pick the best strategy as early as possible. Their use of these AI techniques eliminates project waste, keeps projects on schedule, and reduces the need to make inferences or decisions based on faulty data.

- Bouygues used AI to remake a structural wall, saving 140 tons of steel.

- Simulated Schedules help with resource planning.

- AI minimized waste and better timed some essential projects.

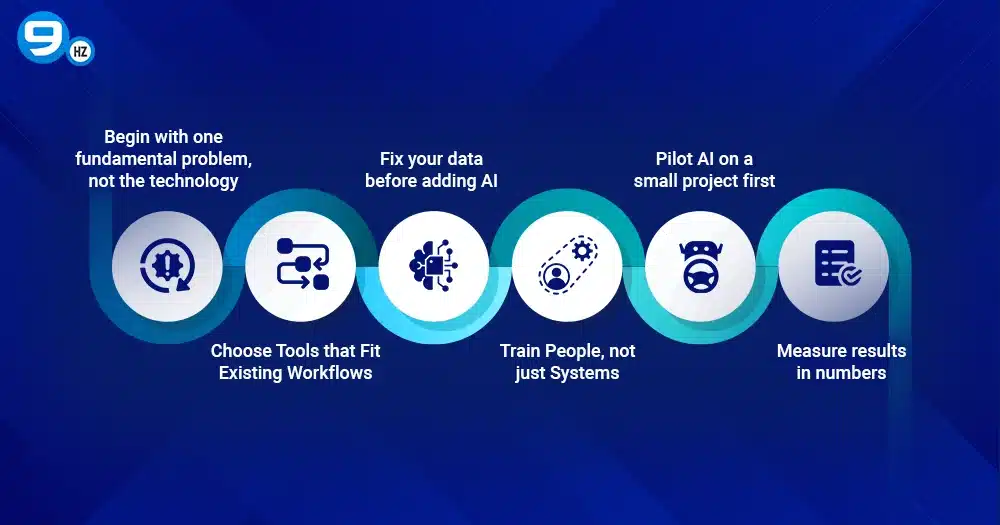

How to get started with AI in construction?

AI is a real game-changer in construction, but its success depends on how the team approaches adoption, not on how advanced it appears on paper. Companies that are cautious and focused on real problems produce faster and with less risk. Let’s get the answer to the question: How to use AI in construction?

1. Begin with one fundamental problem, not the technology.

Yet many AI firms fail because they follow trends rather than address pain points. Teams should begin by identifying one issue that takes time or money to address, like safety incidents, schedule delays, or budget overruns. Clear problems make it easier to measure success and avoid wasted investment.

2. Fix your data before adding AI

Reliable data is essential for AI in construction management. Information is often stored in spreadsheets, emails, and disconnected tools for construction firms. Cleaning up cost data, schedules, drawings, and site reports is solid groundwork. Even simple standardization of data improves results before advanced AI enters the picture.

3. Pilot AI on a small project first

The process of rolling out AI across all projects is risky. Smart teams test AI at a single site, crew, or workflow. Small pilots reveal what works, what breaks and what delivers value. Those who manage to win are trusted and easier to scale later.

4. Choose Tools that Fit Existing Workflows

AI is best incorporated into daily operations. When AI integrates with the platforms they already use, such as project management or accounting systems, construction teams can access tools more quickly. Simple integrations reduce resistance and accelerate adoption.

5. Train People, not just Systems

AI does not replace construction teams. It supports them. Workers, supervisors, and managers need to understand how AI helps them perform their jobs. Short hands-on training builds confidence and relieves fear of new technology.

6. Measure results in numbers

Success metrics are critical for AI use cases in construction. Teams should see improvements in safety incidents, cost savings, schedule accuracy, or productivity. Numbers provide an economic basis for future investments and AI decision-making.

If you’re planning to develop a solution from scratch, start by clearly defining the type of construction software you want to build. Next, choose the right development partner and clearly communicate your requirements to move forward effectively.

Future of AI in the Construction Industry

The future of the construction industry will be primarily influenced by AI. The current worth of the AI in the construction market has been estimated at a mere few million dollars worldwide, but it is expected to increase exponentially in the coming decade. For example, one prediction indicates that the AI building sector will rise from “roughly 1.6-2.3 billion” in the mid-2020s to “between $22-28 billion” in 2030, with growth rates of “20-30% or more annually” as AI is used in planning, safety, and project monitoring. Other estimates put the broader use of AI in construction at $24.7 billion by 2035, indicating rapid growth in demand for these tools to increase efficiency and better manage risk.

This will transform into broader deployment of artificial intelligence in prospective workplaces going forward. Teams will use AI applications in the construction industry for predictive scheduling, real-time safety monitoring, automated reporting, and tracking all machine health information. AI will become more popular among contractors to identify issues sooner and to make quicker decisions. With Asia-Pacific and North America forecasted to be the biggest adopters, Indian companies are also beginning to invest. The high availability and ease of use of these AI tools will lead smaller consultants to incorporate them into their day-to-day work. Those companies that become proficient in using AI today will have a competitive edge in the future.

How Can The Ninehertz Help You Implement AI in Construction Management?

Implementing AI in construction management requires the right mix of technology, industry understanding, and execution. The NineHertz is a trusted construction software development company that helps construction companies move from ideas to real results through tailored Artificial intelligence development services designed for on-ground challenges.

The NineHertz collaborates closely with contractors to familiarise them with the project workflow, data sources, and existing operational gaps. From these insights, the team develops AI solutions to support budget management, scheduling, safety analysis, and decision-making. These solutions seamlessly integrate with primary project management, ERP, and accounting systems, so teams do not need to adapt.

Furthermore, the company efficiently leverages a modern AI tech stack and agile methodologies to generate personalized AI models for predictive analytics, risk notifications, resource analysis, and reporting.

Conclusion

That’s all about how to use AI in construction! As a result, AI is no longer a futuristic notion when applied to the construction domain. It already improves real project planning, reduces risk, controls costs, and enhances safety for companies. AI can enable better decision-making and execution across the project life cycle, from predictive scheduling to on-site real-time monitoring.

However, it is highly important for companies to implement AI properly to reap abundant benefits. It’s not about the technology; the right strategy, clean data, and practical use cases matter more than the technology itself. This is where AI development services come in to help the building sector integrate AI in a confident, incremental way that benefits the industry and allows construction firms to stay competitive in a digitised environment.

Frequently Asked Questions (FAQs)

How is AI currently used in construction?

AI is used by construction firms to control budgets, track costs, ensure site safety, and monitor project progress. AI tools draw sensors, cameras, and reports, and analyze them to help detect risk early. Today, teams are using AI to predict delays, support quality testing, and generate reports.

Is AI expensive to implement for construction companies?

AI does not always need a huge investment. Many companies start with small pilots or subscription tools. Costs vary depending on the use case, project size, and data readiness. If the companies focus on a single key problem, AI can save time and reduce rework.

Can small and mid-size contractors use AI?

Yes. AI is already used by small and mid-sized contractors in the cloud. There is no need for big IT teams to develop such solutions. Many vendors offer fixed pricing, allowing contractors to start small and grow over time.

What is the ROI of AI in construction?

The AI delivers ROI because it slows processes, reduces cost overruns, improves safety, and reduces labor. Firms are often happy with fewer accidents, better schedule accuracy, and lower rework costs. Even modest improvements can make a significant financial impact on a large project.

Does AI replace construction jobs?

AI does not replace construction workers. It supports them. AI handles data analysis, monitoring, and repetitive tasks, while people focus on skilled work and decision-making. AI, in most cases, improves productivity and safety, not reduces the number of jobs.

Great Together!